Precision Injection Molding

Customized Mold And Injection Molding Solutions

20 years of experience in the mold manufacturing industry. Provide you with one-stop solution design, mold making, product assembly and after-sales service.

Learn More

Our company focuses on high - quality mold design and injection molding for various industries. We have advanced facilities and a skilled team, providing custom solutions and stressing quality control with ISO 9001:2015. Our one - stop process ensures high standards and reliable delivery. Our mold design emphasizes innovation to meet unique industry requirements for large - scale production.

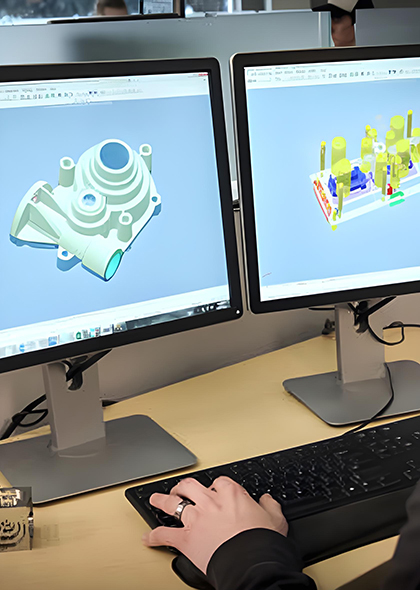

Our mold design services create quality, custom solutions for various industries. Our expert team uses advanced tools for efficient production.

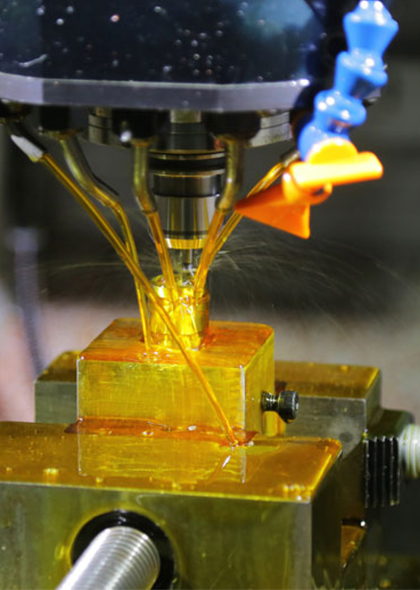

Our manufacturing capabilities offer precision and efficiency. With advanced tech and a skilled team, we deliver high - quality products.

We provide tailored product customization services for various industries. Our team collaborates with clients from concept to production to meet specific needs. Using our expertise, we offer custom solutions in development. We focus on quality and efficiency to deliver great products.

Our quality control process ensures precision and consistency. We adhere to strict standards from design to inspection. With advanced tools, we test products rigorously. Our team uses SPC for early issue detection. We aim to deliver high-quality products exceeding expectations.

Assembly and after - sales services provide quality products and support, build partnerships.

We have a professional technical team to produce drawings for you and meet all your needs from prototype design to production.

Samples Available Now

Both parties clarify and confirm all product and project requirements.

Generate a detailed Design for Manufacturability report to evaluate the feasibility of production.

Provide a comprehensive price quotation based on the confirmed requirements and DFM analysis.

Create an optimized mold design according to the product specifications and manufacturing needs.

Manufacture individual mold parts with high precision and quality standards.

Assemble the produced mold parts into a complete and functional mold.

Conduct trial runs to test and adjust the mold's performance and product quality.

Initiate large-scale production after successful mold trial and quality verification.

We have a professional technical team to produce drawings for you and meet all your needs from prototype design to production.

Samples Available NowAll samples are secure and confidential

We check and confirm sample specifications, dimensions and surface treatment requirements.

Confirm the product drawing.

We will provide you with quotation confirmation according to your product requirements.

You can confirm the prodcut quality by samples order

We select the most suitable manufacturer for your order, produce immediately and follow up the progress

Through advanced testing equipment and professional quality personnel to ensure product quality.

Reliable cooperative logistics providers deliver goods on time and track them all the time

Industry Experience

Factory Area

Employees

Partners

20 years of experience in the mold manufacturing industry. Provide you with one-stop solution design, mold making, product assembly and after-sales service. Let XYS help make your next project successfully!

Provide professional product design support services.

Offer reasonable product structure suggestions from mold experts to optimize mold design.

Provide efficient mass production mold manufacturing advice to avoid common production issues.

Complete T1 quickly within 25 days.